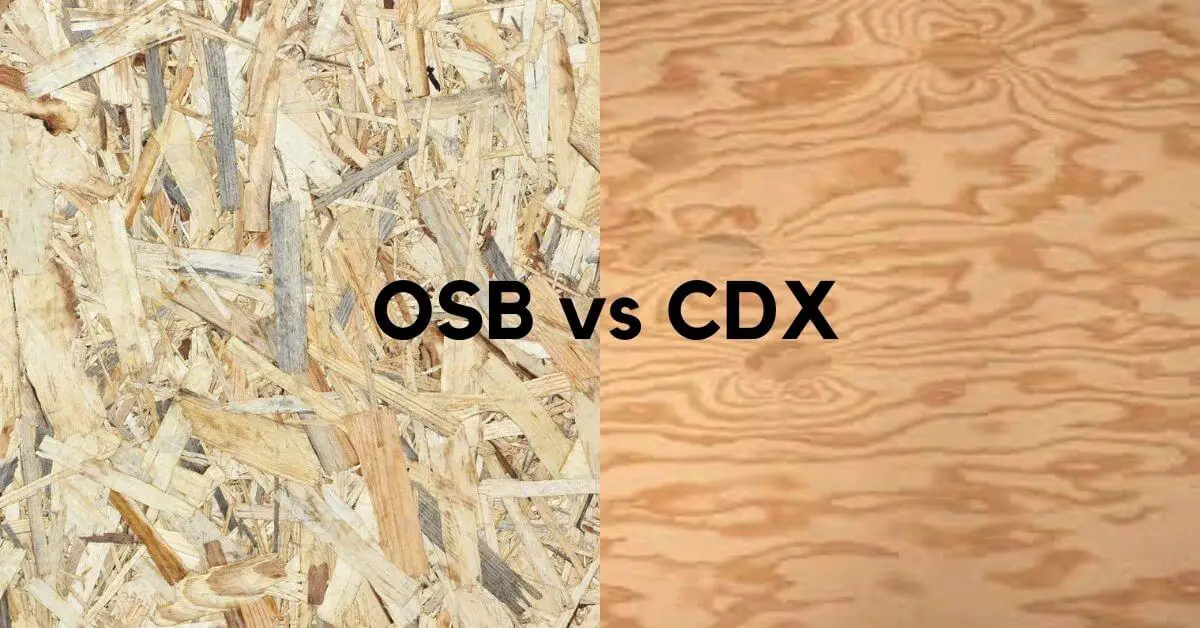

What are OSB and CDX and what are they used for? Often these questions are asked by owners.

Nowadays, engineering wood is increasingly being used. Both OSB and CDX are engineering wood products and this engineering wood is made of real wood but it is not solid wood.

In this blog, we will know what is the difference between OSB and CDX, their pros and cons, and whether it is suitable for your project or not.

OSB

Oriented Strand Board (OSB) is made by compressing rectangular wood chips, resins, and waterproof adhesives into sheets. Two types of glue are used in OSB Isocyanate glue for the inner core and Phenol-Formaldehyde (PF) for the outer layers.

There are four types of OSB. This type depends on their quality and use.

- OSB/1 – General-purpose boards suitable for indoor furniture.

- OSB/2 – Is a structural panel (Suitable for flooring, building panels, and crating)

- OSB/3 – Load-bearing boards (Suitable for damp or humid conditions)

- OSB/4 – Heavy-duty load-bearing boards for use in humid conditions suitable for outside sheathing, and composite load-bearing beams and floor trusses.

CDX

CDX plywood is made of multiple (5, 7, or 11 ) thin veneer sheets of wood. Which are glued on top of each other with high pressure. The name CDX defines itself. C and D define the quality of the veneers. A “C” grade sheet is used on the upper surface and a D grade veneer sheet is used inside. Let’s know about this wood grade in more detail.

The grade of wood is divided on the basis of veneer quality. They are given grades A, B, C, D, and more. A-grade wood is considered the top quality and D-grade wood is considered the lower quality.

This means that medium and low-grade veneer sheets are used in CDX plywood. In CDX the letter “X” stands for exposure, which means the plywood can withstand a little moisture. It cannot withstand moisture for a long time.

But that doesn’t mean it’s weak. It has good strength because the veneer sheets are placed in opposite directions to each other.

CDX plywood is considered suitable for laundry rooms, bathrooms, and areas with mild humidity.

Difference between OSB and CDX

| # | OSB | CDX |

| Weight | A 4′ x 8′ sheet of 1/2-inch OSB weighs around 54 lbs. | 4′ x 8′ sheet of 1/2-inch CDX weighs around 43 lbs. |

| Workability | Due to the excess resin, there may be some problems with its cutting. It does not hold nails and screws well. | Generally very easy to work. CDX holds nails with glue well. |

| Availability | Its large panel is easily available. Its demand is very high all over America and other countries. | CDX does not come in a very large panel. |

| Water-Resistant | OSB performs better in moisture. | It does not perform well in moisture. |

| Price | 23/32″ thickness and 4×8 Sheet size cost about $13.37 | 23/32″ thickness 4×8 sheet size costs about $28.97 |

Uses | Sheathing in walls, flooring, and roof decking. | Exterior walls and roofs. |

Which one is Waterproof? OSB or CDX

OSB performs well in moisture as the resins and adhesives present in it do not allow moisture to penetrate. The second reason is that there are no gaps and layers. OSB is excellent water resistant than plywood. But whenever it absorbs moisture, it changes its shape, takes longer to dry, and goes back to its original state.

On Other Hand, the CDX does not perform very well in moisture because it is made up of multiple thin layers. These layers allow moisture to penetrate easily into the plywood. But CDX dries quickly and comes back to its original shape and size.

Pressure-treated CDX is known to be better for damp areas. It can withstand extreme moisture and it is resistant to termites, fungal decay, and rot. Treated CDX is slightly different from normal CDX plywood. During manufacturing, it is passed through special chemical treatment. so as to enhance the properties of plywood sheets.

Uses

OSB is an excellent choice for wall sheathing, roof cover, sub-flooring, and flooring. OSB is also used to make strong and durable furniture. But they have to be covered with laminates or paint to cover their wood chips. OSB is an ideal choice for the interior or for all those applications that may be exposed to moisture.

Generally, CDX plywood is used for subflooring or interior structure and for all purposes where strength is required. It can get spoiled due to exposure to moisture for a long time, so it should not be used in the dump area.

OSB vs CDX: Which one is good for you?

OSB and CDX are both great products. Which one is good for you? It depends on your purpose of usage. Both materials have their own characteristics and limits

OSB is good moisture resistant. It can withstand moisture and weather. So it is a good choice for floor, wall, and roof sheathing, and for other moist places.

CDX plywood is not good moisture-resistant. But it is stronger and more durable than OSB. It is used for roof sheathing, construction of crates and boxes, garage shelves, sub-flooring, and low humidity. Due to the cross structure of CDX, it can easily withstand heavy weight.

OSB vs CDX Pros and Cons

OSB Pros and Cons

| Pros | Cons |

| OSB is stronger and denser. | OSB can be difficult to paint. |

| It is inexpensive compared to other regular hardwoods. | Does not hold nails and screws well. |

| OSB is manufactured in large, tall panels. | OSB absorbs less moisture and does not dry quickly. Swells with water |

| Versatile with many uses | Not for use with flooring |

CDX Pros and Cons

| Pros | Cons |

| CDX is easy to paint and polish. | CDX is not manufactured in large, tall panels. |

| Hold nails and screws well. | More expensive than OSB. |

| Can be used to finish work | CDX absorbs moisture but dries out faster and more completely |

| Can be used beneath flooring | Potentially not as durable |

Final words

If you still have confusion between OSB and CDX. Before making the final deal. Consult the dealer about your usage and choose the right product.