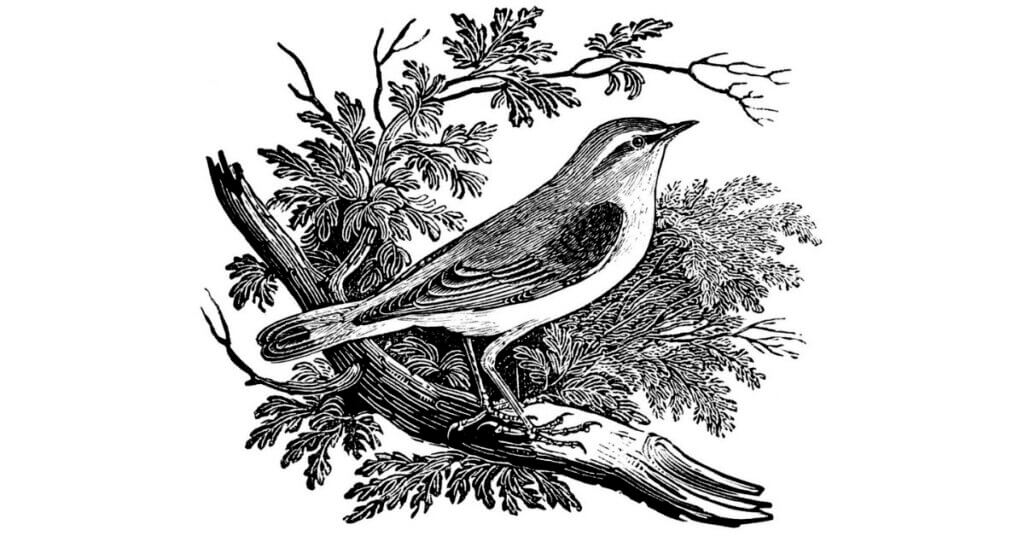

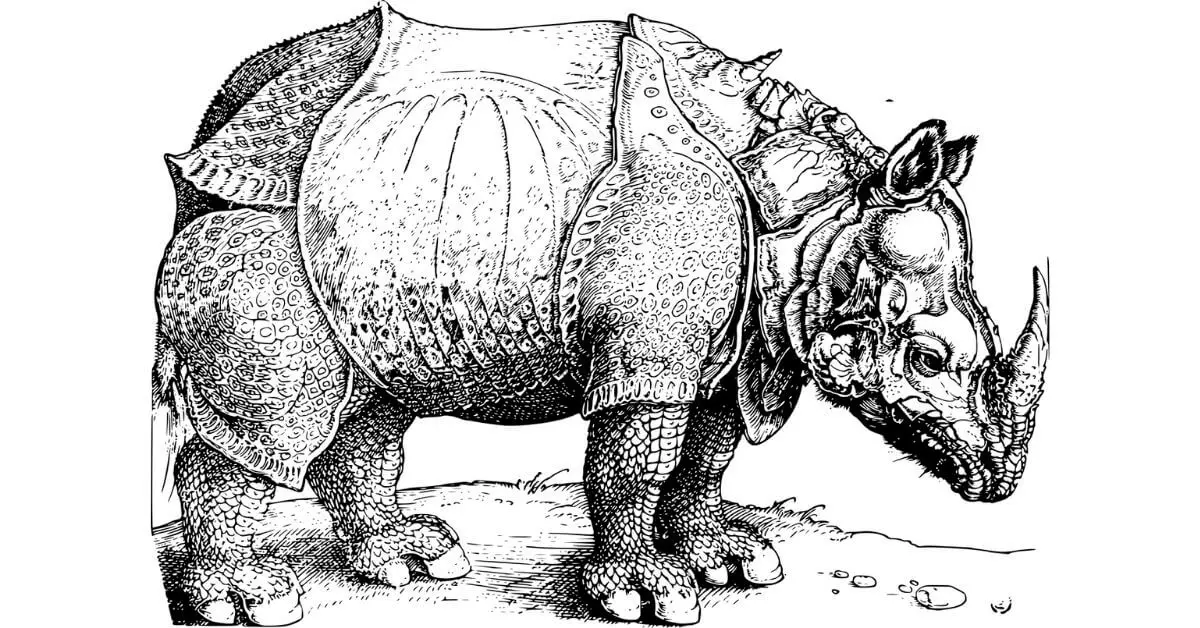

What is Wood Engraving?

Wood engraving is a printmaking method, developed by Thomas Bewick at the end of the 18th century. In this process, an artist cuts an image into the inked woodblock. The main purpose of this Wood engraving is to print the pattern or design on plain paper.

To print, roll the roller with ink (Usually ink is black) on the surface of the woodblock and apply low pressure by placing plain paper on top of the woodblock.

How to do Wood Engraving?

Wood engraving can be done by custom hand tools, hand engraving machines, and automatic Laser machines. Working with custom hand tools requires constant practice and One must be patient in this work for good results.

It can be a bit difficult in the beginning. You should have good knowledge of wood carving.

What are Hand Engraving Machines?

Hand Engraving Machine is a handy machine. This can be easily held by a hand and start wood engraving or carving. This machine has a small motor. Which keeps rotating a shaft. With this shaft, Gravers and other Engraving tools can be attached according to the need, shape, and size.

Motor rotation speed can be increased or decreased. Working with Hand Engraving Machines is much easier and fast than with custom hand tools. But you will have to practice a little for better results. It looks a bit like a hair trimmer.

What is Wood Laser Engraving?

Wood Laser Engraving is an expensive automatic machine. Not much experience is needed to work on this machine. You only have to operate the machine. This is quite easy compared to the hand machine and tools.

In the Laser engraving machine, The piece of wood has to be fixed in this machine. After the correct information about the thickness, length, and width of the wood have to be entered into the machine software.

Through software, you have to upload a design pattern to the computer software and the engraving machine gives the exact same pattern on the wood.

The machine has a laser head that is connected to many wires which control the laser head. It can be moved around on a belt and the laser beam acts as a chisel, incising marks by removing layers from the surface of the material.

Caution: When working on laser engraving, be careful. There is a dangerous ray of laser which can harm you by contact with your body part. Wear gloves and sunglasses.

Some Wood Engraving Tools

Gravers: It is available in many shapes and sizes. It is also known as a burin. Which are used according to their need. Gravers are used to draw lines to clear the space between two lines.

If the Gravers are divided on the basis of quality and material, then it

- Carbon Steel Gravers: Carbon Steel Gravers are cheap tools that are suitable for beginners. They work well when new but don’t retain their sharpness as long.

- HSS Gravers: It is better and more expensive than Carbon Steel Gravers. It can be used by medium-level artists.

- Carbide Steel Gravers: Carbide Steel Gravers are better than Carbon Steel Gravers and HSS Gravers. It retains its sharpness for a long time. But it is an expensive tool.

U-Gouges: By U-Gauges you can cut in recesses like the profile of a bowl. Generally, it is used to make a deep cut and for roughing-out operations.

V-Gouges: This tool is used to separate areas when outlining, adding detail, texturing, or undercutting, is great for detail work. V-tools have two straight edges. Angles are usually 30, 45, 60, and 90 degrees.

Slipstriker: Slipstriker used to remove wood from between thin lines. Or it is used to extract the part between a circle and a curve line.

Scorcher: The forehead of the scorper is wide, it is used to remove wood to a depth. It is generally used between straight lines.

And there are hundreds of tools available that make the work of wood engraving better.

Best Wood for Hand Engraving

Alder

Alder is native to Central America, as well as the northern and southern Andes. It has a smooth surface and a straight grain pattern. The Janka hardness of red alder wood is 590 LBF (2,620 N) and the average dried weight is 28 lbs/ft3 (450 kg/m3). Which is a better value for carving.

Pinewood

There are about 126 species in the pine family. Its uses for lumber, construction, ornamental uses, and wood carving and Engraving. Because it is a softwood its workability properties are great.

Eastern White Pine’s Janka Hardness is 380 lbf (1,690 N) and the Average Dried Weight is about 25 lbs/ft3 (400 kg/m3).

Maple

Mapel can be divided into two types. Soft Maple and Hard Maple. As the name suggests, the hardness and weight of soft maple are low. Soft maple has great workability.

If we talk about Janka hardness is 700 to 950 lbf (4,230 N) and dried weight is about 30.2 to 38.0 lbs/ft3 (485 to 610 kg/m3) depending on species.

`

Cherry Wood

Cherry Wood has been used for wood engraving since long ago. It is a durable wood. Cherry wood is considered suitable for wood engraving. It is light pinkish-brown and turns medium reddish brown with time. Black Cherry is considered suitable for cabinetry, fine furniture, flooring, carving, and Engraving.

Black Cherry, also known as American cherry. Its Janka Hardness is 950 lbf (4,230 N) and dried weight is about 35 lbs/ft3 (560 kg/m3).

Walnut

Walnut is famous for its rich dark chocolate brown. It is mainly used for furniture, cabinetry, gunstocks, interior paneling, wooden objects such as wood carving or engraving.

The Janka Hardness of black walnut is 1,010 lbf (4,490 N) and the Average Dried Weight is 38 lbs/ft3 (610 kg/m3). Its irregular grain can cause problems during wood engraving.

Best Wood for Laser Engraving

Basswood

Basswood has pale white to light brown color. It is easy to work, being very soft and light. Basswood finishes well.

Basswood’s Janka Hardness is 410 LBF (1,820 N) and the Average Dried Weight is about 26 lbs/ft3 (415 kg/m3).

Balsa

Balsa wood is a very soft and light wood species. It can be worked with very easily. Janka’s Hardness of Balsa wood is 67 lbf (300 N) and the Average Dried Weight is about 9 lbs/ft3 (150 kg/m3). Which is very less as compared to other softwood.

Engineered Wood

Engineered Wood is made from real wood. It is also called mass timber, composite wood, man-made wood, or manufactured wood.

Plywood, Particleboard, Examples of Engineered Wood are Medium Density Fibreboard (MDF), etc.

In Laser Engraving, MDF and plywood are used more. But experts consider solid to be more durable and better.

Conclusion

Wood engraving is an art technique that an artist does. Wood engraving printing technique has been done since ancient times. To deliver better wood engraving, you need to choose the right wood and tools.

Comments are closed.