Introduction

Manufactured wood is made by binding the sawdust, fiber, and small pieces of real wood together with strong adhesives. Manufactured wood is also called Engineered wood, mass timber, man-made wood.

Nowadays Engineered wood is widely used for interior and exterior applications. It looks like wood but it is not solid wood. It is stronger and more durable than real wood in some cases. Most of the manufactured wood is available at a lower cost than solid wood.

Manufactured wood products cover almost all the areas of construction. It comes in many textures, sizes, and colors, you can choose it according to your use. It is available in many textures like oiled, lacquered, brushed, unfinished, and many more.

What types of wood are used in manufactured wood products?

Hardwood and Softwood both types of wood are used in manufactured wood products. Some famous hardwood species are maple, oak, walnut, teak, and many more. Some softwood species are cedar, fir, and pine.

Hardwood is stronger and more durable than softwood. Most hardwoods have rot resistance properties and they have close grain. So that there is not much effect of moisture and bad weather.

The top surface of manufactured wood products is made from hardwood and softwood is used for the inside part. Most hardwoods are more expensive than softwoods. Therefore, hardwood is used only in a few portions to make manufactured wood products affordable.

Manufactured wood is used for

Manufactured wood is used for both exterior and interior applications such as flooring, furniture, siding, roofing, decking, fence, and many more. Like solid wood, manufactured wood can be used for a variety of purposes.

Manufactured wood Flooring

Whenever we talk about making flooring, the only material that comes to our mind is solid hardwood. But Nowadays, manufactured wood is used a lot for flooring because solid hardwood is very expensive for large areas. Whereas Manufactured wood can be installed in less budget.

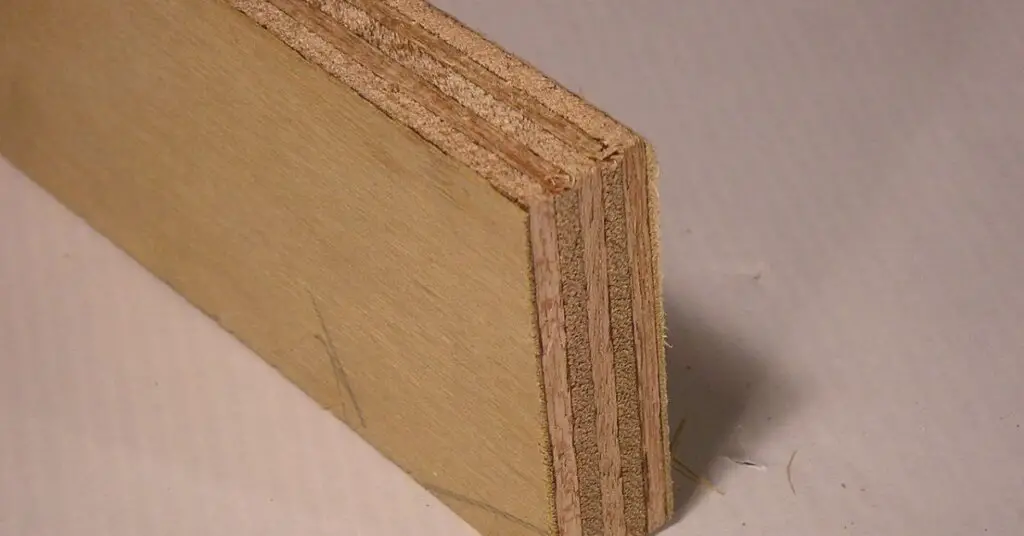

Manufactured Wood has durable, high-performance qualities. Because it is constructed with multi-layers of wood and each layer is placed in a cross direction. Which makes it stronger.

The biggest advantage of using manufactured wood for flooring is that it requires less care and its color and appearance last longer. But for this, you have to choose a better quality product.

Wooden flooring has the most chances of getting dents and scratches. These dents can be from furniture legs and pet nails. The problem of dents and scratches is rare in manufactured wood products. It is harder than solid wood.

Is Manufactured wood good for floors?

It can be a bit difficult to say this directly. Manufactured wood may be better for flooring. It depends on your usage. Manufactured wood is available in many grades and qualities, some can match solid wood and some cannot.

Hundreds of designs and patterns are available in Manufactured Wood Flooring. So we can say that Manufactured Wood can be a great option for flooring. It is economical as compared to solid wood flooring and the other reason is that they can be easily installed.

Decking

Not all manufactured and Engineered Wood Products (EWP) are suitable for outdoor applications. Untreated EWP should not be used for deck framing. Because they rot very quickly. Always use treated manufactured wood products for decking and outdoor applications.

Some manufacturing companies offer warranties on Engineered Deck Beam, While there is no warranty on Solid Wood. They are also easier to install than solid wood as they are already available in sizes and Thickness.

Furniture

Manufactured wood is used for making almost all furniture. Such as Tables, Wardrobes, Chairs, Beds, Sofa, Racks & Drawers.

Although color and grain pattern is important for furniture. Manufactured wood gives wood-like color and appearance. The most commonly manufactured wood products used for furniture are plywood and medium-density fiberboard.

What is the difference between Manufactured Wood and Solid Wood?

Manufactured Wood is a wooden structure made by humans which is made from layers of wood. While solid wood is entirely solid wood.

Manufactured wood and solid wood have a difference in their texture as well as their use. They are used as needed.

| Manufactured Wood | Solid Wood | |

| Structure | Manufactured wood is a wooden layered product. | it is completely solid |

| Durability | In some cases, such as flooring, manufactured wood flooring is weaker than solid wood. Because the upper layer is made from thin sheets. | The floor made of solid hardwood is more durable. It requires minimal maintenance. |

| Stability | It is often seen in manufactured wood that after a few years, gaps begin to form between their layers, due to which it becomes weak. | Solid is more stable but not more than Cross-Laminated Timber (CLT). |

| Installation and workability | Manufactured wood is already available in a variety of sizes and textures. It is easier to install them. | Solid wood is available in the form of lumber, which is more difficult to install. |

| Sanding | It can be sanded only 2 or 3 times because its layers are thin (2 to 3 mm). | Solid wood can be sanded several times. |

| Uses | It is versatile and can be used for almost any wood project. | It is versatile and can be used for all wooden purposes. |

| Cost | Most manufactured wood products are cheaper than solid wood. | Solid is more expensive in many ways |

Types of Manufactured wood?

There are many types of manufactured wood. These are the most common and important ones:

Plywood

Everyone is familiar with plywood. Plywood is the most common material in furniture. Plywood is a wood structural panel and manufactured from multiple veneers (5,7, 9, or 12) of cross-laminated veneer and bonded under high heat and pressure with durable, waterproof adhesives.

There are many types of plywood available. This is the most common and most commonly used.

- Aircraft plywood

- Exterior plywood

- Marine plywood

- Overlaid plywood

- Flexible plywood

All this plywood is manufactured for different purposes. Like Marine Plywood for Marine Application and Aircraft Plywood for Aircraft and so on. Why is plywood is strong?

Plywood Pros and Cons

| Pros | Cons |

| It is available in many sizes and thicknesses. | Water can damage MR grade plywood |

| It is very strong and thin. So workability is great. | Plywood can bend. when longer pieces are used. |

| look like almost any wood | Difficult to identify the quality of a plywood sheet |

| Chemical resistance | Edges also need to be covered with suitable pieces of wood. |

Medium Density Fiberboard (MDF)

Medium-density fibreboard (MDF) is a great product that is made by breaking down hardwood or softwood residuals into wood fibers. MDF wood fibers are combined with wax and a resin binder at high temperatures and pressure.

MDF is much denser and stronger than particle board. Therefore it is heavier than plywood. MDF is mainly considered suitable for making cabinets and cupboards. Read MDF vs plywood.

MDF Pros and Cons

| Pros | Cons |

| Cheaper than plywood. | Compared to plywood, MDF absorbs moisture and water very quickly. and start smelling. |

| MDF has a very smooth surface. So can be used without paint and laminate. | MDF doesn’t hold screws and nails very well. Due to the fine particles. |

| It is very easy to cut as compared to plywood. | There is no wooden grain. That’s why it doesn’t look like wood at all. |

| MDF is easier to paint and seal | The strength is low. so it can’t bear much weight |

Particleboard or Chipboard

Chipboard is made of wood chips or jute-stick chips and a strong binder. Generally, these wood chips are the waste part of the wood. Which come out during the lumbering process. Chemicals are added to the resin or binder to make it waterproof and fire-resistant.

The main uses of particle board are for cupboards, walls, and floor panels.

Particleboard or Chipboard Pros and Cons

| Pros | Cons |

| It is cheaper than MDF and Plywood | It does not hold screws and nails well. |

| This weight is also light. | Its surface finishing is not as good and smooth as plywood and MDF. |

| It does not deny or distort easily. | Low Strength so cannot support heavy Loads. |

| It requires minimal maintenance | Not as Eco-Friendly. The chemicals present in its resin can cause harm. |

Oriented Strand Board

Oriented strand board is a wood structural panel made from rectangular-shaped strands of wood. It is very similar to a particleboard. OSB has great quality with no laps, gaps, or voids.

Oriented Strand Board is more rigid than particle board which can bear much heavier loads. OSB is widely used for roof, wall, and floor sheathing.

Oriented strand board Pros and Cons

| Pros | Cons |

| Large, tall panels are available. | The surface finishing is not good. So that it needs to be covered with other material. |

| OSB is more affordable than plywood and solid wood. | It is a bit difficult to paint it. |

| Easy to cut and use. | It absorbs moisture and swells with water. |

| Versatile with many uses. | Contains formaldehyde which is harmful. |

Cross-laminated Lumber (CLT)

CLT is made by gluing multiple layers of solid lumber using hydraulic or vacuum pressure. Each lumber board is placed side-by-side(cross structure). This structure makes it strong. CLT is mainly used in large construction such as beams, roofing.

Cross-laminated Pros and Cons

| Pros | Cons |

| It is stronger than plywood, MDF, and. It can easily withstand heavy loads. | Its price is higher than plywood and other traditional construction such as steel, or concrete. |

| CLT has great fire resistance properties. | It is more difficult to install than plywood and solid wood. |

| Its thermal performance is very good because it is made of multiple layers of wood. | It is not very widely present in the market. |

| It requires low maintenance | Code restrictions on timber building heights. |

How to clean manufactured wood floors?

The upper layer of Manufactured Wood is soft and thin. That’s why it is important to keep some things in mind while cleaning. Otherwise, you will ruin the floor.

You can choose the vacuum cleaner, soft bristle broom, dust mop, or microfiber mop to clean the dust and stains.

Always choose a better quality cleaner that does not destroy the shine of the manufactured wood floors layers.

Wet your mop and apply slowly on the floor. You can use little vinegar and water, white vinegar in lukewarm water (1 cup per 2 gallons of water). It is totally safe for your Manufactured Wood flooring.

Protect your floor from furniture legs and pet nails. Do not allow any kind of dirt to settle, clean it soon.

Is Engineered Wood Waterproof?

No, anything made of wood is not 100% waterproof. But Engineered wood products perform much better in moisture than solid hardwood.

Comments are closed.