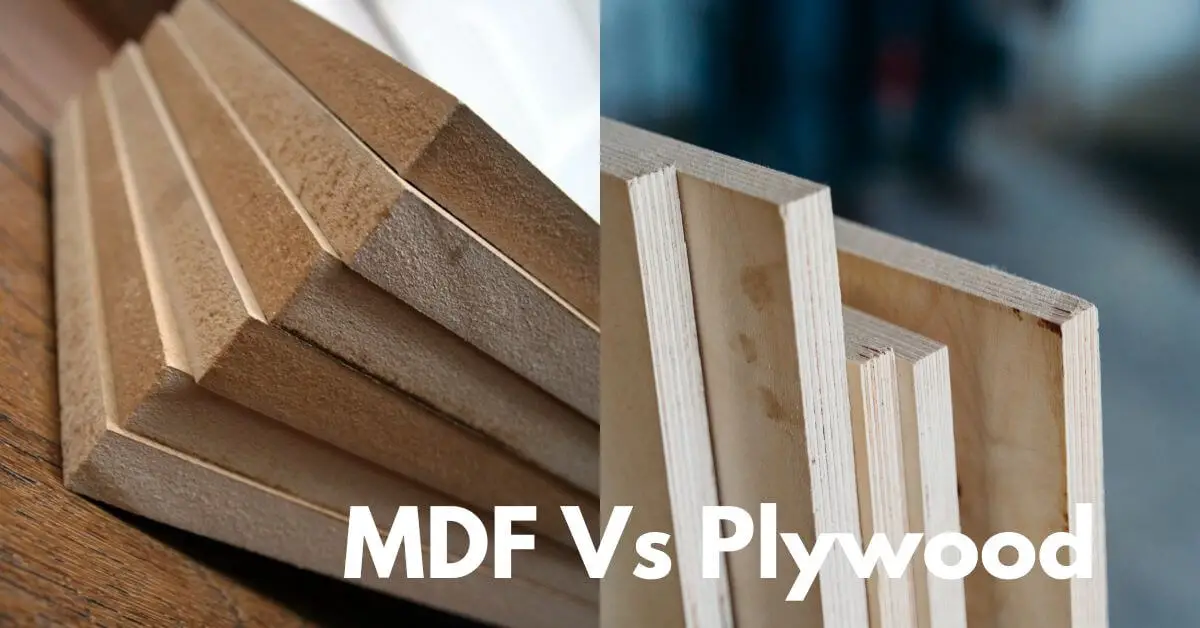

Medium-density fiberboard is made from fine pieces of wood mixed with wax and resin, while plywood is made by gluing several thin layers or “plies” of wood together.

What is a Medium-density fiberboard (MDF)?

Medium-density fiberboard (MDF) is an engineered wood product. MDF board is made by breaking softwood and hardwood into fine pieces and mixing them with wax and a resin binder at high temperature and pressure. It is given the form of a board with the help of a panel.

The density of the MDF board is higher than the plywood. It is used in many applications instead of plywood. It is a strong board and durable, but not as much as plywood. But it is stronger and more durable than a particle board.

It became popular in the US and Europe in the 1980s. Since then it started being mass-produced here. Later it spread all over the world.

What is Plywood?

Plywood is slightly different from the MDF board. It is made by gluing thin sheets of wood (veneer) together. High pressure and temperature are used to glue the veneer well.

Plywood has many grades, and all have their own properties. Different plywood grades are used for different applications as per the requirement. Common grade plywood is used for general purposes such as tables, beds, and cupboards. While marine-grade plywood is used for marine applications such as boats and boat parts.

Plywood is stronger and more durable than both particle board and MDF. Because all layers have their wood grain rotated up to 90 degrees to one another. Manufacturers use an adhesive known as phenol-formaldehyde.

MDF vs Plywood

| # | MDF | Plywood |

| Constituents | Fine pieces of wood mixed with wax and resin and pressed at high temperatures. | Many thin layers or “plies” of wood veneer are glued together at high pressure and temperature. |

| Structure | Smooth surface and knots free. | Rough surface and some knots are present |

| Uses | Suitable for interior purposes. | Suitable for both interior and exterior purposes. |

| Cost | Less than plywood. | It is always more expensive than the MDF board. |

| Durability | It is less durable than plywood. But it is better than particleboard. | It is more durable than particleboard and MDF. |

| Workability | It is easy to work with. | Not easy for finishing needs a sanding and painting process. |

| Moisture Resistance | Poor Moisture Resistance. | Marine-grade plywood has good moisture resistance. |

Medium-density fiberboard (MDF) Board Uses

The MDF board is widely used for indoor applications. It is not suitable for exterior plywood because of its poor moisture resistance. MDF is mostly used for furniture such as cabinets, and speaker boxes because of its strong and finished surface.

MDF boards do not contain grains and knots. Therefore, it can be easily cut and the screw can be applied easily.

1. Furniture and Cabinets

MDF board is a versatile material that can be used to make almost all types of furniture such as tables, desks, and cupboards.

MDF board is mostly used for making cabinets and cabinets. Because the surface on one side of it is smooth. There is no need to apply paint and laminate to the inside of cabinets and shelves.

2. Flooring

The MDF board can be used for flooring. But it is not as durable as hardwood but, it is durable for a few years with regular care and maintenance.

MDF has a good density of 600–800 kg / m³, which is higher than many hardwoods and plywood. It doesn’t warp or swell easily in low humidity areas.

3. Speaker Boxes

MDF board is the first choice to make a speaker box that is available at a lower price than Plywood. MDF is the perfect material for Speaker Boxes.

4. Wainscoting

Wainscoting enhances the splendor of rooms and staircases. It is a great decorating idea. MDF boards are used to make wainscoting.

5. Doors and door frame

The MDA board is used to make bathroom, and kitchen doors. It is necessary to apply laminates to increase durability.

6. Theater set construction

MDF is an excellent construction material for a theater set. Which is long-lasting. Builders like to use MDF boards to build booths and theater sets. Because it is inexpensive and easily available.

7. Decorative projects

MDF boards are used to make DIY TV Trays, Pen Holders, and many other DIY projects.

Plywood Uses

Plywood is one of the most popular multi-purpose engineered wood-based products. It is used widely worldwide. plywood can be used for both exterior and interior purposes.

These are Some uses of plywood

1. Floors, Walls, Roofs, and Other Constructions

Plywood is mostly used for Floors, Walls, and Roofs. Marine-grade plywood is used for floor and roof. Which lasts longer. Standard plywood can be used for the wall.

2. Boats and Boat Parts

Marine Plywood is the best choice for boats and boat parts. It lasts for several decades. To make it more durable, it requires exterior finishing and regular care.

3. Vehicle Internal Bodywork

The vehicle owner likes the wood texture of the vehicle parts. For which they also pay extra money. Plywood is used for car dashboards and bodywork such as.

4. Packages and Boxes

The export departments use plywood for packages and boxes. This is the easiest and safest way. Which is used to send delicate parts from one place to another.

5. Fencing

Wood is used for fencing, but it is less expensive to use plywood for the same area. Lumber can be quite expensive for large areas. Exterior grade plywood can be a good alternative to Fencing.

6. Concrete Shuttering Panels

Plywood is a great option for shuttering panels. It covers a large space and does not have any joints.

MDF Boards Advantages

1. Low Cost

The price of the MDF board is much lower than that of plywood and solid wood. MDF board is a great cheap alternative to plywood. That’s why most constructors and customers prefer to use MDF boards to build applications.

2. Voids or Splinters

MDF has no voids or gaps. Because it is a solid structure. There is no need to add extra wood to the edge to cover the gap, as is the case with plywood.

3. Smooth Surface

MDF board has a smooth surface on both sides so it can be used without polish and paint. In this case, the cost of paint and polish is saved.

4. Easy to cut

It can be easily cut from anywhere as there are no knots or joints throughout the board. Therefore, very little waste comes out of the MDF board.

5. Waterproof MDF

Some people believe that the use of MDF is not suitable for the moisture place, but MDF also comes with an Exterior grade board that can be used for moisture. But it costs more than the normal board.

6. Environment Friendly

The tree does not have to be cut to make an MDF board. It is made entirely of waste wood and wax.

MDF Wood Disadvantages

1. Weaker Than Plywood

There is no doubt that the MDF board is weaker than plywood and solid wood. Because it is made of fine wood pieces and wax. Due to the absence of grain, it can break under high pressure and load. Often it splits during nailing.

2. Maintenance

It requires more maintenance compared to plywood. If the MDF board is used for an exterior application, it requires regular maintenance.

3. Waterproof

The MDF board is comfortable for indoor application. Therefore, it cannot be used in damp places. It absorbs moisture very quickly. This causes the board to swell and weaken after some time, causing it to break.

A waterproof MDF board can withstand less moisture. This grade board costs more than a basic MDF board.

4. Screw Holding

MDF does not hold nails and screws very well. Nailing the MDF board is not easy and it takes time. Use pre-drilling for nailing and screwing.

5. MDF contains VOC

Volatile Organic Compounds (VOC) are contained in MDF Plywood. They are released “off-gas” into the interior. This smell is sometimes not able to smell, and it is not good for health.

6. Natural Texture

Sometimes natural texture is not important. But wood lovers love the wood texture. Plywood and wood have a wooden texture. Which gives the excellent look. But the MDF board is made of wood pieces, so there is no texture in it.

7. Heavy Weight

It is heavier than plywood, so it has faced a little difficulty in working with it. Due to its heavy weight, it is also difficult to transport.

Plywood Advantages

1. Moisture Resistant

Plywood is a good Moisture Resistant material. Plywood can be rot resistant and weather resistant. It does not absorb moisture like MDF.

2. Good Strength and Durability

It has very good strength and durability compared to Medium Density Fiberboard (MDF) and particleboard. It is durable for many decades.

3. Availability

Plywood is available in large sizes compared to solid wood. plywood is available in different thicknesses ranging from 6mm to 32mm. It is used worldwide. So that it is easily available at an affordable price.

4. Easy to Use

Plywood is so much lighter than solid wood and MDF. That makes plywood even more perfect for furniture-making. Can be easily worked with plywood.

5. Plywood Doesn’t Split Easily

Plywood does not split easily due to its cross-layered structure. All veneer layers cross each other. Due to the cross-layered structure, it is more stable and withstands heavy weight and pressure.

6. Nail and Screw Holding Properties

Plywood holds nails and screws very well. Due to the absence of knots in the plywood, the entire plywood is uniform. Therefore nailing is easier.

7. Texture

Plywood offers the finest wooden texture that MDF boards and particle boards cannot. Plywood gives wooden texture at a low price. It absorbs paint and polishes well. Plywood offers the finest wooden texture that MDF boards and particle boards cannot.

Plywood Disadvantages

1. Cost

The cost of plywood is more expensive than MDF board and sometimes it is also more expensive than solid wood. Which makes the customer prefer to use an MDF board instead of a customer plow for normal interior applications.

2. Voids and gaps

As we know, Plywood is made of several wood veneers. Generally, voids and gaps are present in low-quality plywood, which makes the plywood weaker. Nails and screws do not hold well in voids and gaps. Which makes the application weaker.

Carpenter deals with this issue by filling wood glue and filler at the voids and gaps.

3. Regular Maintenance

Commercial grade plywood needs regular maintenance. It also needs to be covered by laminates and paint to protect against moisture. This is an additional expense.

4. Difficult to recognize

It can be difficult for an owner (who doesn’t know much about plywood) to identify quality plywood. There are many types of plywood. Which should be selected on the basis of use.

Customers are cheated many times due to not having enough knowledge about plywood. To avoid this, we always buy plywood from a trusted dealer. Read this How to Identify Marine Plywood?

5. Plywood is Not 100% Waterproof

Nothing made of wood can be 100% waterproof. It is known to be moisture resistant. But yes MR-grade plywood performs better in moisture. But it also gets worse in a few decades.

FAQs

There are two types of plywood based on hardness

Softwood plywood, and hardwood plywood. Softwood plywood is made from fir and pine wood and Hardwood plywood is made from oak, poplar, maple, cherry, larch, etc.

Can you paint an MDF board?

Yes, you can paint the MDF board, but before painting, you must apply a primer and seal the MDF. MDF accepts primer and paints well.

What is the process of making plywood?

Many different manufacturing companies have their own process of making plywood. But there are nine common processes for making great plywood.

These nine processes to make plywood:

- Log storage

- Log debarking and bucking

- Heating the logs

- Peeling the logs into thin layers (veneers)

- Drying the veneers

- Gluing the veneers together

- High pressing the veneers in high heat

- Plywood cutting

- And other finishing processes

What content in MDF?

| Contains in MDF | Percents |

| Wood Fiber | 82% |

| Urea-Formaldehyde Resin Glue | 9% |

| Water | 8% |

| Wax | 1% |

Conclusion

MDF and Plywood both are amazing materials. Both materials also have their advantages and disadvantages. MDF and Plywood are used on the basis of their properties.

MDF board would be the best option if you want a low budget and material for interior applications. If you want material for an exterior application that can withstand moisture, then go with plywood.

Read others articles

Comments are closed.