Marine Plywood

Marine-grade plywood is superior-quality hardwood plywood that is widely used for marine applications such as boats, the boat of parts, ports, and exterior uses. Marine plywood is the best furniture material. It can withstand any stream weather conditions for long periods.

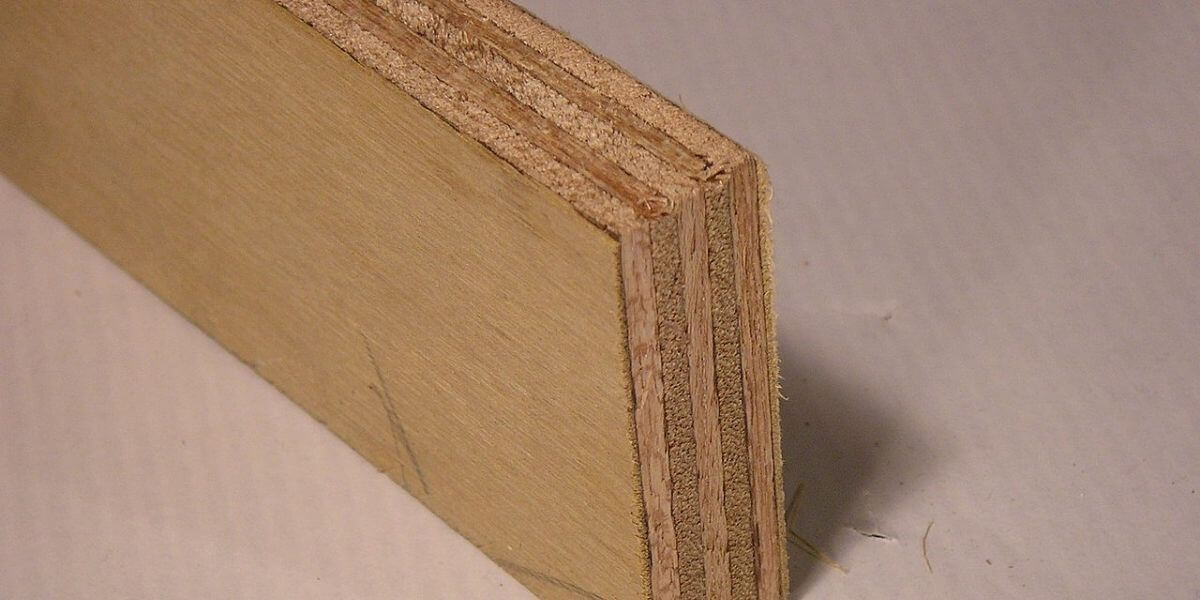

Standard interior plywood is made of 3 – 5 layers while 9 to 11 veneer layers are used to make marine-grade ply boards. These all layers are glued with high-quality waterproof glue. Which lasts for many decades and requires less maintenance.

BWP Plywood

The BWP grade stands for the boiling waterproof grade. This grade of plywood is widely used for outdoor applications that are likely to be exposed to water and moisture for extended periods.

It can be exposed to water and moisture for a long time. BWP marks are boiling waterproof as per standard norms. So it is suitable for most home furniture requirements.

Due to the amazing properties, most carpenters and interior designers love using BWP plywood to make kitchen cabinets and under-basin storage. It is also widely used for bathroom doors, building walls, and storage units. Because it is performing better in moisture.

| # | Marine Plywood | BWP Plywood |

| Grade | Marine-grade plywood. | Boiling Water Resistant grade plywood. |

| Cost | More expensive than that of BWP Plywood. | Cheaper than marine plywood. |

| Water resistance | Marine-grade Plywood is good waterproof. But it is not 100% waterproof, it starts to damage after some 72 hours. | BWP grade is waterproof plywood. |

| Uses | It is a perfect material for extreme weather and marine applications. | It is used for interior and exterior. Mostly used for waterproof applications. |

| Voids and Gaps | Marine-grade plywood does not contain gaps and voids. | It has minimal core gaps |

| Knotholes or Cracks | Marine-grade plywood is 100% knotholes or cracks free. | WBP plywood may still contain these |

| Weight | Veneer sheets used in marine-grade plywood are weighed. | It is a little lighter. |

| Quality Veneers | The wood veneer of Western Larch or Douglas-fir is used to make marine-grade plywood. | BWP plywood is also made of hardwood veneer sheets. |

Marine-grade Plywood Uses

Marine plywood is a high-quality type of plywood that is specifically designed for use in marine environments. One of the primary applications of marine plywood is in constructing boats and marine vessels. It is ideal for building boat hulls, decks, and other structural components. It is also used for Outdoor Furniture, Exterior Construction, Bathroom, Subflooring, and Kitchen Cabinetry.

BWP Plywood Uses

BWP (Boiling Water Proof) plywood is specifically designed to withstand exposure to water and moisture. It is treated with special chemicals that make it highly resistant to water damage. BWP plywood is used for Kitchen Cabinets, Bathrooms, Outdoor Furniture, Boat Interiors and Roofing.

Properties of Marine-grade Plywood

1. Consistent Thickness and Strength

Marine plywood is known for its absence of voids and gaps, ensuring uniform thickness and strength throughout the sheet. So that it can be easily cut from anywhere. It is easy to work with due to its uniform thickness.

2. Quality Veneers and Waterproof Glue

Marine plywood is made from veneers of western larch or Douglas-fir hardwood, with all these layers glued together using waterproof glue. Some tips on How to Identify Marine Plywood?

3. Smooth Finish

Both the surfaces of marine plywood are smooth so that moisture cannot penetrate inside, and due to the smooth surface, there is no need for painting and polishing.

4. Bending Capacity

Industry experts emphasize that premium plywood should not bend beyond 18 mm. The bending capacity of marine plywood is less than 18 mm. So, whenever you buy marine plywood, ask about the bending capacity from the dealer.

5. Strength and Flexibility Combined

Marine plywood is strong as well as flexible. Marine-grade plywood can be easily cut and bent in any shape and size. It can easily hold heavy weight. So it is also used for the roof.

Properties of BWP Plywood

1. Uniform Thickness

BWP grade boards are manufactured with a uniform thickness to make them more stable. It has minimal core gaps, resulting in a solid and durable board suitable for various applications.

2. Reinforced Strength

MWP plywood has good strength and shape retention ability. So it has the ability to bear more load than other plywood.

3. Waterproof Plywood

BWP plywood is resistant to wear, water, termites, and insects. This waterproof quality significantly extends its lifespan, making it a reliable choice for applications exposed to challenging environmental conditions.

4. Cheaper

Having similar properties to marine plywood, BWP plywood is a cost-effective alternative. Despite its comparable properties, the price of BWP is much lower than marine plywood.

Final Words

Marine Plywood and BWP both have their own properties. So, it is essential to know about Plywood’s applications and properties before buying it. Marine Plywood and BWP plywood are available in different thicknesses ranging from 6mm to 32mm.