Marine Plywood is designed for moist or damp environments like boats and docks. It is made with high-quality, waterproof adhesives and usually consists of several layers of wood veneer. It is stronger and more stable than ordinary Plywood.

Some wood species used to make marine Plywood are Douglas fir, cedar, and evergreen hardwoods. Marine Plywood is more expensive than standard Plywood due to its better moisture resistance. It is resistant to rot, rust, and insect infestation.

Marine Plywood is excellent for boats, boat parts, decks, and other marine applications. It can be difficult for an ordinary person (who needs to learn about Plywood) to Identify Marine Plywood.

But I am sharing some tips that will help you identify real marine Plywood.

1. Smooth Finish

Marine plywood is smooth on both sides, while regular plywood has rough surfaces. The smooth surface prevents moisture and dust from entering and makes plywood more durable. Due to the smooth surface it can be used even without paint.

2. Bending capacity

Good plywood does not have much flex; experts say that “plywood that bends more than 18 mm may be weak.” So whenever you buy marine-grade plywood, check the bending properties as well.

3. Weight

Marine plywood is made from solid wood veneers, so due to the solid veneer and higher density, it weighs more than regular plywood. You can check the weight of the ply by lifting it from one side.

Although the weight of plywood depends on the thickness of the plywood, but on average, marine plywood weighs around 30 to 40 pounds per 4×8 foot sheet (1/2 inch thickness).

4. Knots and Defects Free

Knots-free and A-grade veneer is used to make marine-grade plywood with no defects. That’s why marine plywood is more weather and moisture-resistant than standard plywood.

Several types of marine-grade plywood include AA, AB, BB, MDO, and HDO. The quality and price of each grade vary from each other.

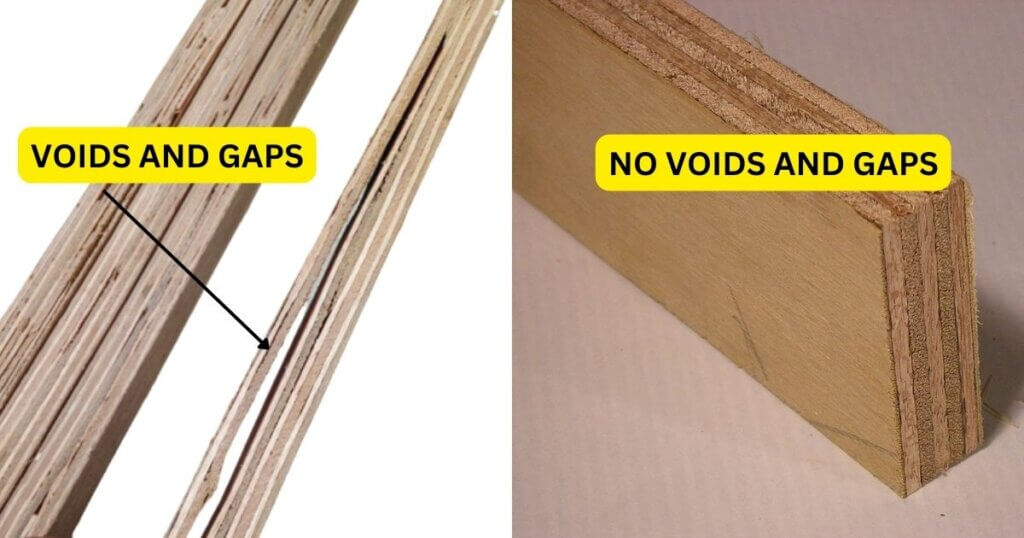

5. Voids and Gaps

Generally, Voids and gaps are present in low-quality and standard plywood. So the moisture can quickly penetrates the plywood and spoils the plywood quickly.

You don’t see the spaces and gaps in marine-grade plywood. All the veneer sheets of marine plywood were glued together very well.

6. Number of Layers

Marine grade plywood typically has an odd number of veneer layers, with a minimum of three layers. However, the the number of veneer layers may vary depending on the specific grade and thickness of the plywood.

7. Quality Veneers

Marine Grade is made with the highest quality of veneer sheets, which are naturally moisture- and weather-resistant. Marine plywood is most commonly made from Douglas fir or Pine.

Ask for a small piece of plywood so that you will know what kind of veneers is used in the plywood and what is the density of the plywood.

8. Check the label

While purchasing a marine plywood, be sure to check the certification label of the plywood. BS 1088 is for British Standard Specification Marine Plywood. It is used by marine plywood manufacturers worldwide.

BS 1088 plywood must use a good quality adhesive and veneer sheet proven to be highly resistant to weather, rot, and dry heat.

9. Price

Marine-grade plywood is more expensive than standard plywood because marine-grade plywood is manufactured using high-quality waterproof adhesives, such as phenol-formaldehyde, which are much more costly than the adhesives used in standard plywood.

A 4×8 foot sheet of exterior plywood costs roughly $40 a sheet, while the same size sheet of Marine plywood costs $100-$160 a sheet, so it is a cost of a 4x factor.

10. Buy From Trusted Store

You are paying a good amount for marine plywood so it is important that you get original marine plywood. Try to buy from a trusted shop that you know.

Conclusion:

If you want to purchase marine plywood for boats and parts of boats, you will never want to compromise with quality.

Identifying Marine Plywood is difficult. So there are a few things to remember before purchasing marine plywood. So that you cannot be cheated in the market, all the tips above will help you choose real marine plywood.

If you are looking for alternatives to marine plywood read this article Marine Plywood Alternative.

Comments are closed.