Glue-laminated timber is also known as glulam timber. Several pieces of wood are glued together under pressure and heat, forming a large wooden structure; this structure is known as Glue-laminated timber. Glue-laminated timber is used as vertical columns, horizontal beams, and arches. Glue-laminated wood can be easily bent into curve shapes and is available in a variety of species and appearances.

Glulam has been used extensively for decades for commercial and residential projects. Due to its specialty, every constructor likes it. It is perfect for long beams and curved designs that also provide strength with beauty. Laminated boards have better mechanical strength than other materials and resistance to rot and burn.

Advantages of Glulam Timber

Availability

It is widely available in different sizes in the market. Glulam timber is available in the market in 45mm x 45mm up to 250mm x 1800mm x 30m sizes.

The minimum diameter of the column to support the roof should be 9X9 inches and 10-12 feet in length. So, finding a complete piece of wood is rare. Therefore glulam timber is a valuable material for these types of jobs. Because glulam timber is made by joining many blocks of wood, it is readily available in large to small sizes.

Flexibility

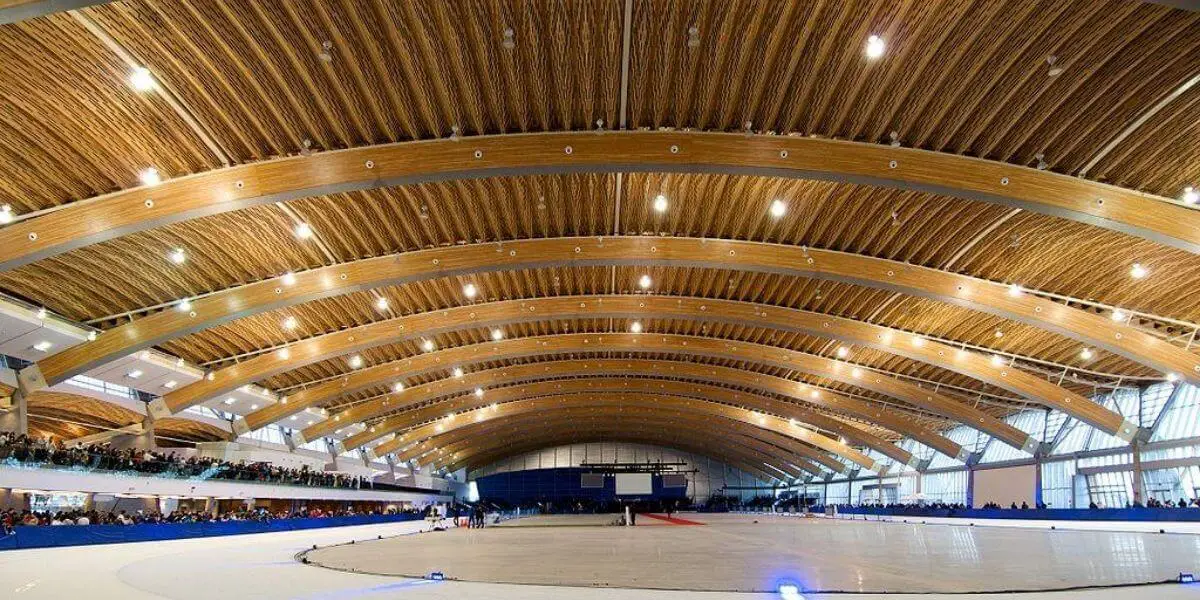

Glue-laminated Timber is primarily used to support roofs because we know that a strong and flexible column is required to support a heavy roof.

It can be easily used anywhere in the roof structure. It is made of several wooden layers to be placed at different angles, so it is easy to bend compared to wood.

Glulam lumber can be easily bent into various angles depending on the requirements. Ordinary lumber takes a lot of effort and time to make curves.

Easy To Use

Glulam wood is easier to use than steel and concrete because it does not require heavy machines. It can be easily cut and bent into any shape and size.

Durability

Wood has excellent weight-bearing capacity. Wood can withstand pressure and stress because of its flexibility and can withstand stress without damage, while steel and concrete crack.

Glulam is 2-3 times more durable than steel and concrete. To increase the durability of a woodworking project, we must choose a suitable wood species of Glulam. That is, we should select the wood species according to our project.

Like if we are using Glulam for the roof beam and pillar of the house. That’s why we should choose such wood with a good strength ratio to weight.

If we need wood for the swimming pool, we should take such Glulam, which is resistant to moisture and weather, So can last long in contact with water, and will not deteriorate.

Fire-Resistant

Some species of wood, such as Ipe wood, have good fire resistance. The fire resistance of glulam wood is quite good compared to ordinary wood because it is a solid structure.

Anti Termite

A common type of wood is likely to be hollow and rotten inside. Its structure is weak due to termites and ants. And that structure becomes completely hollow and weak within a few years.

But glulam wood is completely solid because it is made by joining several layers. That’s why it is less prone to termites or insect attacks.

Disadvantages of Glulam Timber

Price

When we talk about the price, the price of glulam timber is always higher than that of ordinary lumber because the cost of production is associated with the price.

Maintenance

Regular maintenance is required to ensure that the adhesive joints remain tight and the wood does not deform.

Transportation

Glulam beams are large and heavy, making transportation to a construction site more difficult and costly.

Fire resistance

Glulam timber is a not have the same fire resistance as other building materials such as steel or concrete.

Read other articles: